Table of Contents

ToggleNails are made and designed for different purposes. Their design varies with varying purposes. It is used as a fastener to hang something. Nails usually have a sharp point on one end known as the point and a flattened head on the other called the head and the shaft is known as the shank. Nails are basically used for joining and installing various equipments required in the household. They are called the Fasteners. Along with nails, screws also play a vital role in construction and carpentry. Both of them go hand in hand.

Nails and Screws

Nails are teamed up with screws for completing any task regarding woodmaking and household. The limitation of the first is fulfilled by the other and viceversa. They complement each other.

Nails are stonger and cheaper than screws so they are used for heavy tasks such as housemaking and installing huge floors. They enter inside the objects due to their shape. Screws are used for low or mid- level tasks due to their less weight. Screws are prefered for temporary tasks because they can be removed easily after the work is done.

Nails are more flexible, can work under pressure and are less visible than screws. Nails lack the tensile strength which is required in high-stress structural projects that is present in the screws and can perform the work that the nails cannot.

1. PORTER-CABLE Brad Nails

These portable nails are 18 gauge brad nails having 18 fastener gauge. They are a pack of 900 nails. There are 100 fasteners per stick and the masterpack has 10 nails in all. This is one of our bestsellers and our consumers swear by its sturdiness and convenience. It can also be gifted for housewarming.

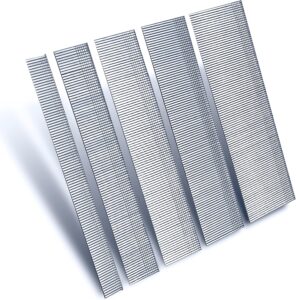

2. SimCos18 Gauge Brad Nails

This pack of nails is available in 5 different sizes as mentioned above varying from short to middle to long size. These are the most commonly used sizes (not many short nails are put in the pack) because one short size can cover for most short nail demands. The T-shaped head and Chisel point with strong penetrability will make it easy to use. It has galvanized surface which will keep the nails rust and corrosion free. The brand also gives 100% assurance about the product and offers refund or exchange if not satisfied about it

3. SHALL 18 Gauge Brad Nails

This pack contains 4000 count 18 guage brad nails in four sizes as mentioned above – 1000 of each. This multisize provided makes sure to meet most of the fastening needs. These nails are of standard size and diameter and generally fit most electric, power and air guns. Great for light-duty to heavy-duty jobs. They easily penetrate through many different materials without showing any signs of deformation. They are made of high quality galvanized steel which offers resistance against rust and corrosion and has a high tensile strength. The entire packaging is done in soft EPE pearl cotton, in a 3-layer corrugated box to prevent breaking through the delivery.

Brad Nails VS Finish Nails

Brad nails are made of 18 gauge steel wire. Thinner the nail, higher is its gauge number. Thus the brad nails are very thin which makes its trimming inside the wooden object easier. Its thin nature avoids splitting on sensitive surfaces. Its lean structure provides a neat and refined result in the undertaken projects. They are ideal in works requiring minute finishing because of their small diameter and the trimming work will expose minimal amount of the hole and might not require filling the surface before painting.

Finish nails, on the other hand, have a 15 guage steel wire has a larger diameter due to low guage number. The increased thickness ensures more load-bearing capacity and it can easily deal with thicker objects. The larger diameter leaves a bigger hole after the fastening process so it needs filling to be done to smoothen the surface and cover up the unevenness. So they are not preferred to work on delicate areas.

So in heavy-duty operations where the benefits of both is required, brads and finish nails work together thus ensuring the fulfillment of the task.

For hanging shelves, Brad nails are used because of their smaller diameter. It provides a refined finish as the trimming done does not require the remaining area to be filled before painting.